Fundamental Properties of Friction Stir Welded Al 7136 Including Effects of Post-Weld Artificial Aging

ABSTRACT

Recently, a new 7XXX series aluminum alloy designated 7136 has been developed by Universal Alloy Corporation (UAC) for aerospace applications. Base material properties of 7136 are compared to friction stir welded joint properties. Additionally an investigation into post-weld artificial aging and corrosion was conducted. The FSW joint properties and aging behavior of 7136 was also compared to 7075-T73 and some of the replacement alloys for 7075-T6 which have been identified by the Navy, specifically 7055-T74 and 7249-T76. Trends in the overall aging behavior of 7XXX series alloys, friction stir welded in the T7x condition are discussed. Preliminary results show that the corrosion resistance of 7XXX series alloys welded in the T7x condition can be significantly enhanced by the application of post-weld aging following FSW. Post-weld aging is also required in order to stabilize the microstructure in 7XXX series alloys, which would otherwise continue to naturally age indefinitely as indicated in the literature. Microhardness, electrical conductivity, tensile and exfoliation corrosion test results, as well as an assessment of the metallurgical characteristics, is presented.

INTRODUCTION

Friction stir welding (1) has been shown in to join various aluminum alloys including the hard to join aluminum alloys such as 7136 and 7249 (2). Interest in these high strength aluminum alloys has grown with 7249-T76 and 7055-T74 being two of the alloys identified by the United States Navy as replacement alloys for 7075-T6 (3).

The 7136 and 7249 extrusions were received in the W temper. The 7xxx alloys are not stable in the W temper and consequently require some artificial aging process to stabilize the material. Without artificial aging, the material will continue to naturally age for many years (4). For each sample tested in the as-welded condition, a stabilization heat treatment of 121oC for 24 hours was utilized. Post-weld artificial aging was also used to stabilize the FSW samples, as well as increase or restore the resistance to corrosion. Electrical conductivity and microhardness were used to characterize the effect of the heat treatments on the joints and parent material. It has been shown that a strong correlation exists between the electrical conductivity and the resistance to stress corrosion cracking on the as welded and artificially aged FSW joints in 7xxx alloys (2).

EXPERIMENTAL PROCEDURE

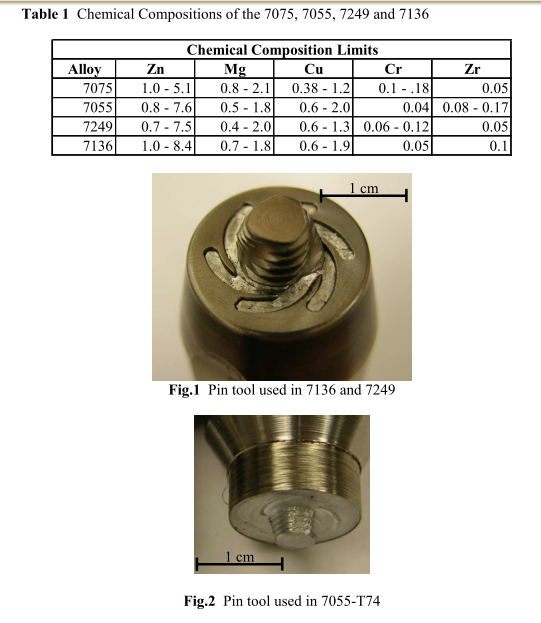

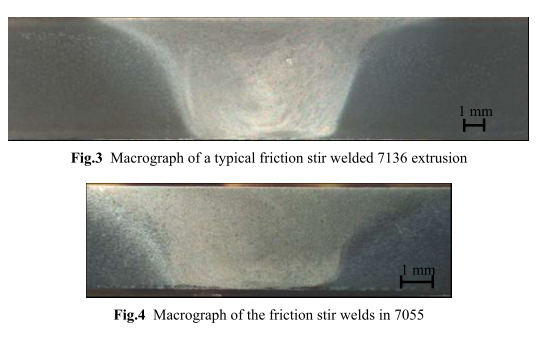

The compositions of the 7136, 7249, 7055, and 7075 aluminum alloys investigated are shown in Table 1 (wt %). In the 7136 and 7249 extrusions, the welds were made in the intermediate W temper and in the overaged T76 temper with a 6.35 mm nominal thickness. The 3.2 mm nominal thickness 7055 was received in the T6 temper and some of the material was aged to the T74 temper at 177oC for 4 hours prior to welding. The pin tool used on the 7136 and 7249 extrusions included a WiperTM feature (patent pending) on the shoulder and a tapered threaded pin with three twisted flats as shown in Fig.1. The pin tool used for FSW of 3.2 mm 7055 extrusions is shown in Fig.2.

Post weld artificial aging was used to stabilize the microstructure and increase the corrosion resistance of each material. Tensile properties were obtained with 203 mm wide transverse specimens with a 12.7 mm gage section per ASTM E8. Exfoliation corrosion testing was performed per ASTM G34 specifications. The 7136 and 7249 extrusions welded in the W condition were tested after a 24hrs stabilization treatment at 121oC and also received a post-weld artificial age (PWAA) to take the material to the T76 overaged temper. In the 7136-T76 and 7249-T76 extrusions, the tensile and corrosion properties were again taken after a 24hrs stabilization treatment at 121oC, as well as an additional artificial aging of 12 hours at 121oC followed by 2 hours at 163oC. The 7055-T651 and T7451 material was tested after a 24hrs stabilization treatment at 121oC and the PWAA condition by aging at 177oC for 4 hrs. Additionally, the 7055-T7451 material received a similar 12 hours at 121oC followed by 4 hours at 163oC treatment. The additional post weld age treatments for the T7x tempers was chosen based on some recent work in 3.2 mm 7075. It was shown by Widener et al. (5) that an additional short term post weld age at 163oC can raise the electrical conductivity and improve the exfoliation resistance in FSW of 7075-T73 with potentially higher tensile strengths than 7075-T6 aged to T73. For the 7136 and 7249 extrusions, the spindle speed was 400 rpm with a travel speed of 305 mm/min. The 7055 extrusions were welded with a spindle speed of 500 rpm and 254 mm/min.

The electrical conductivity mapping of the samples was done with a Hocking AutoSigma 3000 sensor. The profiles of each sample were taken from the root of the weld. The microhardness profiles are shown in the Vickers scale (VHN) and are taken across the midsection of the weld cross-section.

RESULTS AND DISCUSSION

Microstructure

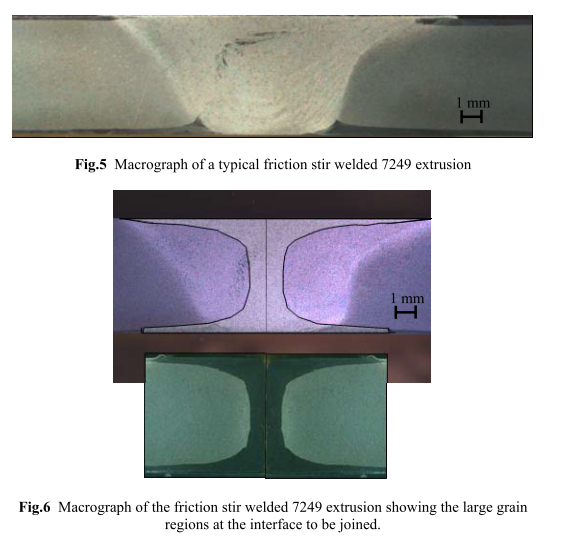

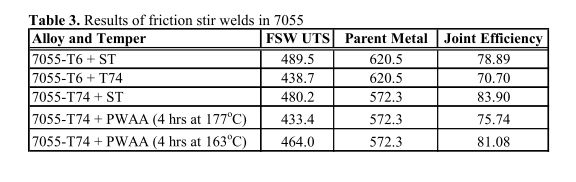

With the exception of the 7249 extrusions, an abnormally large grain region at the edges to be joined did not exist. Figs. 3 and 4 show macrographs transverse to the welding direction of the 7136 and 7055 extrusions, respectively. There was no visual difference between the material welded in the W511 condition and the T76 temper. The 7249 extrusions in the W511 and T76 tempers had large grains at the interface to be joined a seen in Fig.5. A majority of the large grains are recrystallized to the fine equi-axed grains due to the FSW process. A trace of the abnormal grain still exists in the nugget on the retreating side of the weld. Fig.6 gives an indication on the amount recrystallization of the large grains in the nugget of the friction stir weld.

Mechanical Properties

Tensile specimens were taken transverse to the welding direction and were pulled according to ASTM E8 specification. The ultimate tensile properties and joint efficiencies of the friction stir welds in 7249 and 7136 in each temper are shown in Table 2.

The joint efficiencies of the friction stir welds in the 7136 extrusions were lower than that of the 7249 extrusions due to the limited amount of material available for producing an acceptable DOE in the 7136 alloy. All results for this alloy should be viewed as preliminary results. Welding in the overaged T76 temper versus the W511 temper resulted in a negligible drop in the ultimate tensile strength; however a 3% drop in UTS was observed when the additional over aging treatment was applied.

The tensile tests of the friction stir welds in the 7249 extrusions show the strongest static strength when the material is welded in the W511 condition and stabilized using a T6 treatment of 121oC for 24 hours. No appreciable difference in static strength was seen, however, between welding in the W511 temper followed by aging to the T76 temper versus welding in the T76 followed by a stabilization treatment. Only a 2% reduction in UTS was observed by applying an additional post weld artificial age to material originally welded in the T76 condition.

The results of the friction stir welds in 7055 are shown in Table 3 for the as welded and post weld aged specimens in each starting temper. The strength of the FSW specimens was the highest in the 7055-T6 material, as expected. However, the strength of the T74 material is only slightly lower than that of the T6 material (9 MPa). The 7055-T6 post weld aged to T74 shows a more significant drop in the UTS when compared to starting in the T74 temper. In each condition, adding a post weld age depreciates the UTS of the joint. A low temperature treatment (163oC) for a short period of time (4 hrs) appears to have the least effect on the joint efficiency.

Electrical Conductivity and Microhardness

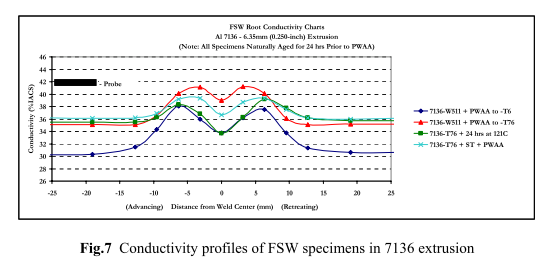

The conductivity profiles of the root of the FSW specimens in 7136 extrusions are shown in Fig.7. The curve of the W511 material to T6 shows the conductivity of the parent material is converted to that of a T6 temper (~31% IACS) with the nugget exceeding that at about 34% IACS to about 38% IACS in the TMAZ/HAZ. The conductivity of the parent material in the other specimens exhibits a conductivity of a T76 temper in this material (>35.5% IACS). It is interesting to note that the nugget of the material joined in the T76 temper with a stabilization treatment of 121oC for 24 hours has a lower conductivity (~34% IACS) than that of the parent material, and that in the as-welded, stabilized condition both the W511 and T76 tempers produce a weld nugget with the same electrical conductivity. The highest overall conductivity of the FSW weld zone was achieved when welding in the W511 temper followed by PWAA to the T76 temper. The nugget had a conductivity of about 39% IACS and peaked at about 41% IACS in the TMAZ/HAZ. The conductivity achieved in the weld zone is significantly higher than the parent material. This behavior is often observed when post weld artificial aging is applied to FSW joints, and seems to indicate that the nugget and TMAZ are aging at a faster rate than the parent material.

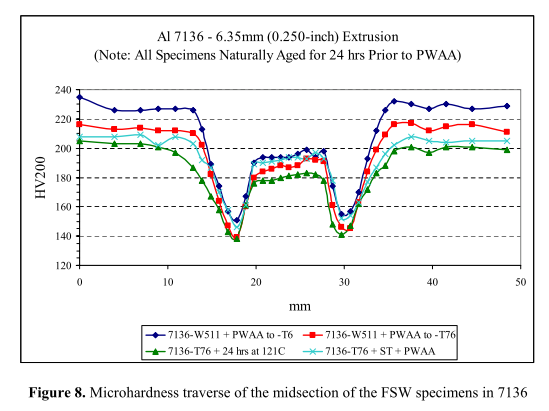

The microhardness profiles across the midsection of the FSW cross section in the 7136 extrusions are shown in Fig.8. The highest VHN is seen in the material joined in the W511 temper and aged to T6 in both the parent material and the nugget. The material joined in the W511 temper and aged to T76 exhibited the next highest VHN in the parent material, however, the nugget was lower than the material joined at the T76 temper with an additional overaging treatment. The material joined in the T76 temper plus a stabilization treatment of 121oC for 24 hours showed the lowest microhardness profile.

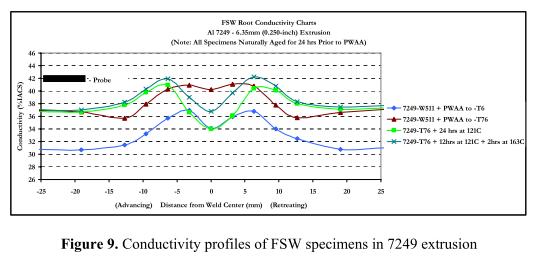

The conductivity profiles of the root of the FSW specimens in 7249 extrusions are shown in Fig.9. The curve of the material joined in the W511 temper and aged to T6 showed the lowest conductivity profile, yet the nugget and TMAZ/HAZ had a higher conductivity (~34% IACS nugget, ~37% IACS TMAZ/HAZ) than that of the parent material (~31% IACS) due to the overaging caused by the weld thermal cycle. When the W511 FSW specimens are aged to a T76 temper, the conductivity of both the parent material and FSW zones increase to a minimum of 36% IACS. The nugget and TMAZ show almost an equivalent conductivity around 41% IACS with a dip in the HAZ to about 36% IACS. The parent material of the FSW specimens joined in the T76 temper and the W511 temper aged to T76 all had an electrical conductivity of about 37% IACS. When welding in the T76 temper and given an additional overaging treatment, the conductivity of the nugget and TMAZ/HAZ equal or exceed that of the parent material. The conductivity, although lower in the nugget, is higher than the local minima seen in the HAZ of the W511 material aged to T76. This trend also appears in the FSW specimens in 7136 extrusions.

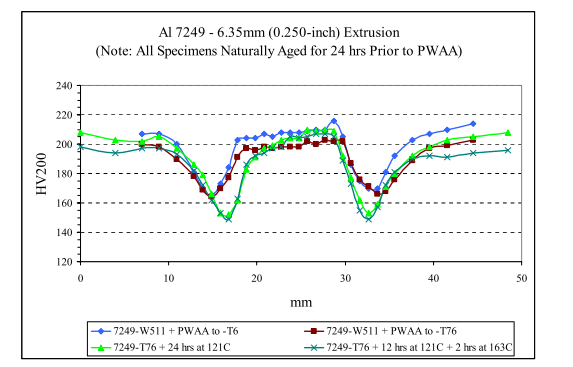

The microhardness profile across the midsection of the cross section of the FSW specimens in 7249 extrusions is shown in Fig.10. The highest VHN is seen in the material joined in the W511 temper and aged to T6 in both the parent material and the nugget identical to that of the FSW specimens in the 7136 material. Unlike the FSW specimens in the 7136 material, the material joined in the T76 temper regardless of the PWAA treatment, had a lower VHN in the HAZ than the material joined in the W511 temper plus aging to a T6 or T76 temper. There was no noticeable difference in microhardness values in the PWAA treatments of the FSW specimens joined in the T76 temper. Both did, however, exceed the VHN values of the nugget of the W511 material plus PWAA to T76. Apparently in 6.4 mm material with this pin tool, the HAZ of 7249 is least affected when welded in an intermediate stabilized temper, followed by post-weld aging. It is also interesting to note that the heat affected zone minimum occurs farther away from the weld center, and that the application of the additional T76 PWAA to the W511 material did not result in a significant drop in the HAZ hardness minimums, only the nugget and parent material microhardness values were appreciably lowered.

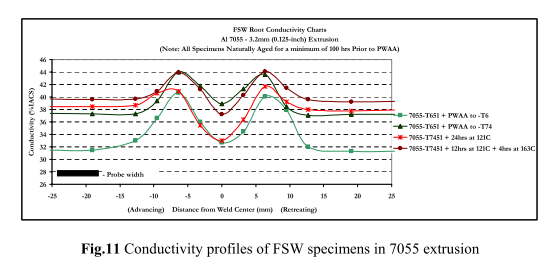

The conductivity profiles of the FSW specimens in the 7055 extrusions are shown in Fig.11. The conductivity of the 7055 material joined in the T651 temper plus a stabilization treatment exhibits a similar behavior to the 7249 material in the same condition. The conductivity of the nugget (~33% IACS) and TMAZ/HAZ (peak ~41% IACS) is higher than that of the parent material (~31% IACS). This same trend is seen when the T6 material is aged to a T7451 condition with the nugget at 39% IACS and the TMAZ/HAZ peaking at about 44% IACS. The conductivity profile of the FSW specimens in the 7055-T7451 material with an additional overaging treatment showed a higher IACS in the parent material (~40% IACS) and was slightly lower in the nugget (~37% IACS) than the T651 aged to T7451.

Exfoliation Corrosion Test

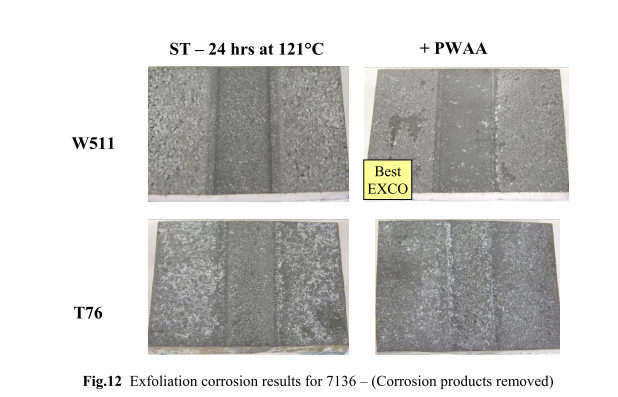

The exfoliation corrosion results for 7136 are shown in Fig.12. It was hypothesized that welding in the T76 temper, followed by an additional PWAA treatment may lead to better exfoliation corrosion results, as reported by Widener (5) with 3.2 mm 7075-T73 material; however, that was not the case here. The best exfoliation corrosion results were achieved by welding 7136 in the stabilized W511 condition followed by PWAA to the T76 temper. Pitting was observed in the HAZ of all cases tested; however it was lightest in the W511 + T76 condition.

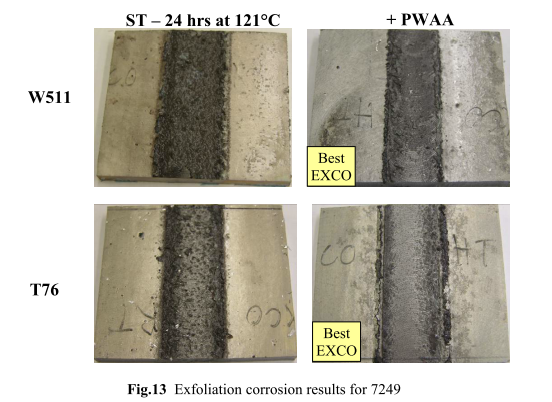

The exfoliation corrosion results for 7249 are shown in Fig.13. The best exfoliation corrosion results were achieved by the addition of a higher temperature PWAA treatment to the as welded material. Pitting was observed in the HAZ of all cases tested, but was negligible in the W511 + T76 condition and very light in the T76 + PWAA condition. It was also noted that in all cases the parent material remained cathodic to the weld zone as evidenced by the preferential corrosion of the weld zone and the lack of corrosion in the parent material adjacent to it. The T76 plus the additional PWAA treatment had the best exfoliation response in the weld nugget. The weld path scallops were still evident after 48 hours in EXCO solution. Either of the W511 + T76 or T76 + PWAA samples investigated could be viewed to have acceptable exfoliation corrosion response.

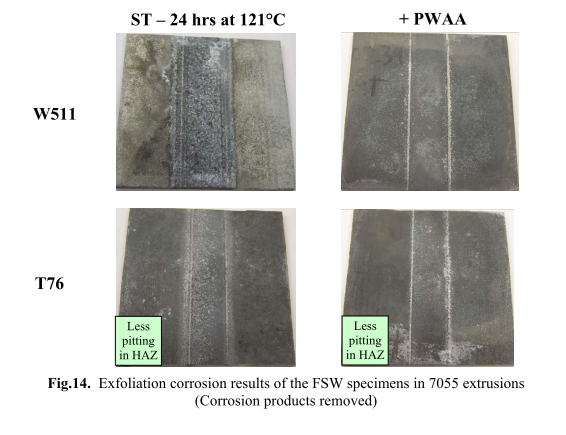

The exfoliation corrosion results for 7055 are shown in Fig.14. Pitting was observed in the HAZ of all cases tested, but was least in the T76 + ST and T76 + PWAA conditions. Severe attack was observed in the W511 + ST condition.

CONCLUSIONS

When joining the higher strength 7136, 7249 and 7055 aluminum alloys, post weld aging is necessary to stabilize the microstructure in the friction stir welded regions. Additional overaging treatments can also result in an improvement in the corrosion resistance of the alloys. The aging from a peak temper (T6) to an overaged T7x temper as well as an additional overaging treatment of the FSW specimens welded in the T7x temper will raise the electrical conductivity. Based on previous work by Li et al. (2), this will result in an improvement or restoration of the stress corrosion cracking (SCC) resistance of the FSW weldments, and has been shown here to be able to restore or improve exfoliation corrosion resistance. Further evaluation of the results of the FSW process on 7136 is needed in order to raise the joint efficiency and better understand the response to PWAA treatments. That research is ongoing in the Advanced Joining Laboratory at the National Institute for Aviation Research at Wichita State University. The 7249 extrusions with large grains at the edge to be joined are more susceptible to weld path alignment.

ACKNOWLEDGEMENTS

This work was funded in part by grants from the State of Kansas NIS Program and the Federal Aviation Administration. The material (7249 and 7136) was generously provided by Iulian Gheorghe of Alu Menziken Aerospace/Universal Alloy Corporation. The 7055 material was provided by John Barnes of Lockheed Martin.

REFERENCES

1 Thomas, W.M.: Friction Stir Butt Welding, International Patent App. No. PCT/GB92/02203 and GB Patent App. No. 9125978.8, Dec. 1991, U.S. Patent No. 5,460,317.

2 Li, Z.X., Arbegast, W.J., Wilson, A.L., Moran, J., Liu, J. “Post-Weld Aging of Friction Stir Welded 7249 Extrusions,” Proceedings of the 6th ASM International

Conference Trends in Welding Research, Pine Mountain, GA, USA April 2002.

3 Frazier, W. E., “High-Strength, Corrosion-Resistant Aerospace Aluminum Alloys,” JOM January 2003.

4 Nelson, T.W., Steel, R.J., and Arbegast, W.J., “Investigation of Heat Treatment on the Properties of Friction Stir Welds,” ASM International Aeromat Conference Presentation, 2001.

5 Widener, C., Kumar, B., Burford, D., and Talia, J.E. “Evaluation of Post-weld Heat Treatments to Restore the Corrosion Resistance of Friction Stir Welded Aluminum Alloy 7075-T73 vs. 7075-T6,” Thermec 2006, International Conference on Processing & Manufacturing of Advanced Materials, Vancouver, Canada, July 4-8, 2006